A new age of manufacturing has officially begun—not in Silicon Valley or Shenzhen, but in low Earth orbit.

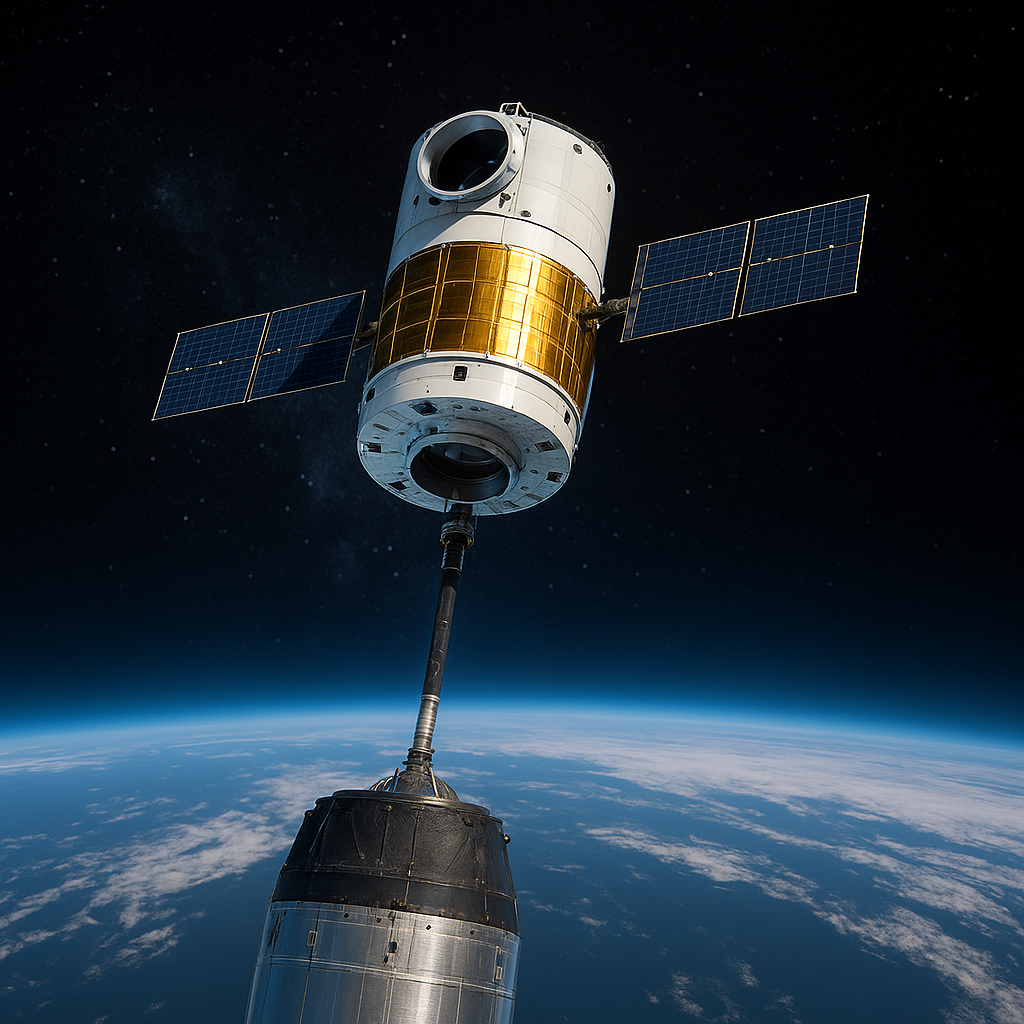

Onboard a recent SpaceX Transporter-14 rideshare mission, the ForgeStar-1 satellite, developed by UK-based startup Space Forge, launched into orbit with a bold mission: to prove that the future of semiconductor manufacturing belongs in space.

This marks the UK’s first dedicated in-space manufacturing satellite, fully engineered and assembled in Cardiff, Wales. ForgeStar-1 won’t just orbit the Earth—it aims to forge materials in microgravity and vacuum conditions that are impossible to replicate on Earth.

“We’ve built and launched Britain’s first manufacturing satellite—and it’s alive in orbit. That’s a massive technical achievement,” said Space Forge CEO Joshua Western. “Now we move to proving we can create the right conditions for manufacturing in space. This is the start of a new era.”

🔧 Why Manufacture Semiconductors in Space?

ForgeStar-1’s mission is rooted in a simple but powerful insight: space is the ultimate clean room.

- Perfect vacuum

- Extreme sub-zero temperatures (without cryogenics)

- Near-zero gravity

These conditions are ideal for growing high-performance semiconductor crystals—especially those needed for next-generation AI data centres, quantum computing, and defence systems.

The satellite uses space-derived crystal seeds to initiate chip fabrication processes for materials like gallium nitride (GaN) and silicon carbide (SiC)—both crucial for power-hungry AI and military-grade electronics.

While ForgeStar-1 won’t return its creations to Earth, it serves as a proof-of-concept: testing thermal shielding, orbital maneuvering, and safe deorbit protocols, including a spectacular end-of-mission fireball if recovery fails.

🛰️ A Path to Commercial In-Space Fabrication

ForgeStar-1 is just the beginning. Its successor, ForgeStar-2, is planned to be the first spacecraft to fabricate and safely return semiconductors from orbit. The long-term plan? To scale production with reusable satellites capable of one- to six-month missions—ultimately launching 100+ space forges per year.

The goal is clear: make in-space manufacturing not just possible, but commercially viable, where the value of the materials produced outweighs the cost of launching the satellite.

🚀 Implications for Space Autonomy and the Defense Sector

For those following the rise of space autonomy and militarized tech infrastructure, this is a pivotal moment.

- In-orbit chip production would reduce dependence on terrestrial supply chains.

- Military-grade semiconductors could be produced in secure, uncontaminated orbital labs.

- And with future recovery systems, entire constellations of autonomous fabrication satellites could serve both civil and defense sectors on demand.

Imagine a future where AI-powered drones, autonomous satellites, and quantum battlefield networks are supplied not by factories in Taiwan or Texas—but by satellites silently forging components in orbit above Earth.

🌌 The Big Picture

As Space Forge looks ahead to ForgeStar-2 and beyond, one thing is certain: manufacturing is no longer confined to Earth.

We are witnessing the first sparks of an industrial revolution in orbit—a space-based supply chain that could power everything from AI supercomputers to autonomous weapons, all while bypassing geopolitical bottlenecks and gravity itself.

The forge has launched. The countdown to a truly autonomous space economy has begun.

📣 Stay Ahead with Space Autonomy

At SpaceAutonomy.ai, we track the frontier of in-orbit manufacturing, autonomous systems, and defense tech. Want to stay ahead of the curve?

✅ Follow us @Space_Autonomy on X and @SpaceAutonomy on Instagram

🔗 Read the latest at SpaceAutonomy.ai

🛰️ Join the conversation shaping the future of warfare, tech, and orbital infrastructure.

S-11